V65D Series

"Digital DC Motor Drive V65D Series" utilizes the DSP technology and modular design, it could replace analog

type dc motor drive completely, so V65D DC Motor Drive is very suitable for the refurbished market of the DC

Motor Drive of traditional machinery, the application market of the power requirement of high-torque in

low-speed.

Main Features

-

Using the technology of DSP, control is accurate.

-

The driving range for DC Motor is from 35A to 2,000A.

-

Two-quadrant DC motor unidirectional control and four-quadrant DC motor forward and backward two-direction

control.

-

Selections of feedback signal, Armature voltage, ACTG or DCTG and Encoder.

-

Auto detection and adjustment to Phase sequence (R-S-T).

-

Regenerate type of brake, saving energy.

-

Field weakening control.

-

Magnetic loss, motor overload protection.

-

Self- diagnosis function, maintenance is easy.

-

Support RS-485 interface and MODBUS protocol.

TC-2060 Model

TC-2060 can be widely used in various materials, such as paper, film, rubber, fiber, metal foil, etc., and it

is suitable for unwinding/rewinding in various process conditions for automatic tension control.

Multi-functions of operation panel with multi-functions of terminal input can match production conditions for

various mechanic equipment, having two-chips of CPU design, the capability of high-speed operation, and perfect

control software, which shows the performance of accurate operation and stability.

Main Features

-

The functions of unwinding / infeed, center proportional linkage, and rewinding / receiving can be set by

the internal DIP switch of TC-2060.

-

It includes the digital type of line-speed proportional linkage function, which can make material stable

tension in the process of production.

-

Multi-level P.I.D computing capability can fast stabilize material tension variations in the process of

production, meanwhile,having reverse P.I.D. Computing Function and can cooperate with the servo controller

for active feeding.

-

Accepting tension detection signal (LMS series, PDSA series of tension detectors) as the tension signal

source for computing material tension in the production process.

-

Large subtitles high brightness LED numeric display, which can monitor remotely, switch-key can change the

display unit kg.N.%... in operation.

-

There are four rows of LCDs that can monitor four data records simultaneously.

-

Two sets of terminals accepted external analog input signals that can be set for automatic tension control,

manual tension control, and taping tension control.

TC-2050 Series Model

TC-2050 & TC-2050P tension controllers use the feedback signal of high-precision LMS series of tension

detectors to stabilize tension control. It uses two chips of 16 bits of the microprocessor to do computing

division, having the performance of fast and stable tension control, and is suitable for tension control for

unwinding/infeed, center proportional linkage, and rewinding / receiving.

Main Features

-

The functions of unwinding / infeed, center proportional linkage, and rewinding / receiving can be set by

the internal DIP switch of TC-2050/P.

-

It includes the digital type of line-speed proportional linkage function, which can make line speed in

accelerating or decelerating until the stop keeps stable tension control.

-

Multi-level P.I.D, which can present a fast and stable function when speed is variable at any time.

-

Large subtitles high brightness LED numeric display, which can be selected by the parameter "SRC" to

display different units, such as kg.m/min, etc.

-

The parameter function is symbolized by English abbreviations and can be easily operated without relying on

the manual.

-

There are LED window displays, "RUN" is for running, "CENTER" is for center proportional linkage, "WINDER"

is for unwinding/rewinding, "SENSOR" is for the abnormal detector, "ERROR" is for the abnormal message.

-

Working with LMS series of load cell, rated load of 5Kg ~ 1,000Kg (50NM~10,000NM).

TC-2030 Series Model

TC-2030 utilizes a pulse generator to count the rotation number of rolls on the unwinding or rewinding roller,

according to the setting value of the material's thickness, calculating the change of diameter of unwinding or

rewinding roll and reaching the purpose of tension control.

Main Features

-

Having 8 sets of internal memory functions and eight production materials can be memorized.

-

Having the shuttle dial for setting parameters.

-

Can preset the initial tension, to modify the unstable condition in the start caused by mechanical friction.

-

Large subtitles high brightness LED display, through display cycle-key, it can display output(Kg),

percentage(%), and diameter value.

-

Having auto. and manual control functions.

-

The terminal's output signal of DC 0 ~ 10V could directly control the torque controller, a current-control

type of vector Inverter, DC motor drive, and servo motor drive.

-

The multi-function terminal can control the operation to stop output, and remotely control diameter to

reset, accelerate gain, and forward / reverse switching.

TC-2010 Series Model

TC-2010 receives tension detected signal from LMS series, PDS series of tension detector, built-in 16 bits

high-speed microprocessor with the function of calculation, presenting fast and stable tension control

performance.

Main Features

-

It includes a digital type of line-speed proportional linkage function, which can maintain stable tension

control from starting,accelerating, or decelerating to stopping.

-

Multi-level P.I.D, which can present a fast and stable function when speed is variable at any time.

-

Large subtitles high brightness LED numeric display, which can be selected by the parameter "SRC" to

display different units, such as kg.m/min, etc.

-

The parameter function is symbolized by English abbreviations and can be easily operated without relying on

the manual.

-

There are LED window displays, "RUN" is for running, "HIP" is for the high limit, "LOP" is for the low

limit, and "ALM" is for the abnormal messages.

-

The terminal that can receive a set of encoder or pulse signals is regarded as the source of the line-speed

signal.

LMS-050 Series Model

The LMS series high-precision tension detector is a very precise combination part, with the TC series tension

controller, the control speed and tension show outstanding control and stability performance.

Main Features

-

Utilizing high-tension steel plate and a special heat-process technique to achieve the rigidity of impact

resistance and high stability.

-

The detection loop uses a high-frequency linear differential circuit coil, which has good anti-interference

ability.

-

LMS series tension detector has various specifications and is easy to install.

EPD-3008-A Series Model

Edge Position Controller EPD-3008-A

EPD-3008 can accept an Ultrasonic or Infrared-type edge position detector to drive an electric cylinder and

achieve material edge alignment.

Main Features

-

Built-in DC motor feedback loop that can select a drive unit, which accepts feedback signal, and enhance

the accuracy and response of edge alignment.

-

Combining the operation panel and controller together can mount on the surface of a plate or externally

stand-alone for operation.

-

Accepting vary of Edge Position Detectors.

-

Working to vary of drive units, such as EPM series electric cylinders.

-

Built-in the loop of edge position output signal that can connect to the external high-capacity drive unit

and enlarge drive capacity.

-

Equipped with RS-485 communication that can connect to computers.

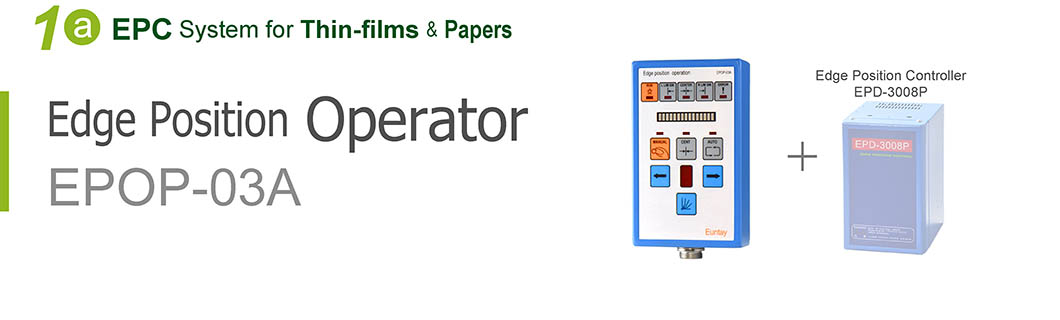

EPD-3008P Series Model

Edge Position Controller EPD-3008P

The same as the EPD-3008 function; the operation panel and controller of the EPD-3008P are separated, and the

controller can be installed in the control box independently or hidden in the mechanism.

Main Features

-

Built-in DC motor feedback loop that can select a drive unit, which accepts feedback signal, and enhance

the accuracy and response of edge alignment.

-

Combining the operation panel and controller together can mount on the surface of a plate or externally

stand-alone for operation.

-

Accepting vary of Edge Position Detectors.

-

Working to vary of drive units, such as EPM series electric cylinders.

-

Built-in the loop of edge position output signal that can connect to the external high-capacity drive unit

and enlarge drive capacity.

-

Equipped with RS-485 communication that can connect to computers.

EPOP-03A

Edge Position Operator EPOP-03A is a remote operation kit of Edge Position Controller EDP-3008P, it uses

communication transmission to transmit operation instructions to Controller and display detector's detected

position on the operation panel.

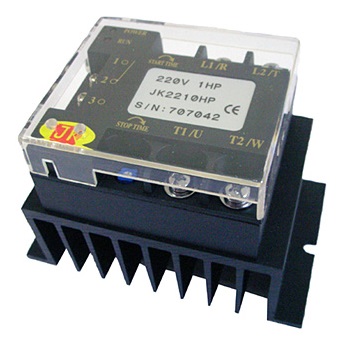

Three Phase Soft/Start Model

Soft-start motor controller, use the blowing machine's motor, mixing machinery, milling machinery, smash

machinery, overhead cranes, oil pressure elevator, soft start, reducing the instantaneous starting current.

When the motor abnormality, can protect the motor.

Main Features

-

Soft start time and start torque can be adjusted, let soft starter smooth.

-

3 starting ways can be choice in this machine: slope starter, current-limit starter, current-limit and

kick starter.

-

Use the S.C.R. control: No contacts, no arc, no wear and tear, the equivalent of semipermanent life.

-

Cooling fans has temperature control, the cooling sheet working at 55C, and stop at 45C, this design can

extend use-life of fans 2-3 times.

-

The controller inside electronic sensor of CT: overload protection, input power loss the phase protection,

motor block protection, controller over temperature protection, exceed sensitive reaction and no thermal

effect, not affected by ambient temperature.

-

The machine has 3 sets output connection points: The output point when starting (Running), after running

the output contacts (by Pass), and output point for system abnormal (NO, COM NC).

-

Protection structure : IP20

Three Phase SP Series Model

Soft-start motor controller, used in the pump motor, hydraulic motor, pumping stations, water equipment, soft

start and soft stop, so that the water pump motor system can eliminate water hammer, pipe will not let the

noise affect the quality of the living.

Main Features

-

Soft start time, start torque and soft stop time can be adjusted, let soft starter smooth.

-

3 starting ways can be choice in this machine: slope starter, current-limit starter, current-limit and

kick starter.

-

Use the S.C.R. control: No contacts, no arc, no wear and tear, the equivalent of semipermanent life.

-

Wiring easy: installation of 3 in 3 out, save the coast of hand wiring.

-

This controller is microprocessor with the function of automatic light/heavy loading revision and torque

control.

-

Cooling fans has temperature control, the cooling sheet working at 55C, and stop at 45C, this design can

extend use-life of fans 2-3 times.

-

The controller inside electronic sensor of CT: overload protection, input power loss the phase protection,

motor block protection, controller over temperature protection, low load protection, exceed sensitive

reaction, and no thermal effect, not affected by ambient temperature.

Three Phase - Soft Start of OL Series Model

Soft-start motor controller, use the blowing machine's motor, mixing machinery, milling machinery, smash

machinery, overhead cranes, oil pressure elevator, soft start, reducing the instantaneous starting current.

When the motor abnormality, can protect the motor.

Main Features

-

Soft start time and start torque can be adjusted, let soft starter smooth.

-

3 starting ways can be choice in this machine: slope starter, current-limit starter, current-limit and

kick starter.

-

Wiring easy: installation of 3 in 3 out, save the coast of hand wiring.

-

The machine has 3 sets output connection points: The output point when starting (Running), after running

the output contacts (by Pass), and output point for system abnormal (NO, COM NC).

Three Phase - Soft Start Of Microcomputer Series Model

Soft-start motor controller, use the conveyor's motor, overhead cranes, soft start, reducing the instantaneous

starting current. When the motor abnormality, can protect the motor.

Main Features

-

Soft start time and start torque can be adjusted, let soft starter smooth.

-

Start way: slope starter.

-

Use the S.C.R. control: No contacts, no arc, no wear and tear, the equivalent of semipermanent life.

-

Built-in reverse polarity protection circuit and output overcurrent (short-circuit) protection circuit

-

Wiring easy: installation of 3 in 3 out, save the coast of hand wiring.

-

This controller is microprocessor with the function of automatic light/ heavy loading revision and torque

control.

-

Cooling fans has temperature control, the cooling sheet working at 55C, and stop at 45C, this design can

extend use-life of fans 2-3 times.

-

The controller inside protection function: Input power loss the phase protection, controller over

temperature protection, exceed sensitive reaction and no thermal effect, not affected by ambient

temperature.