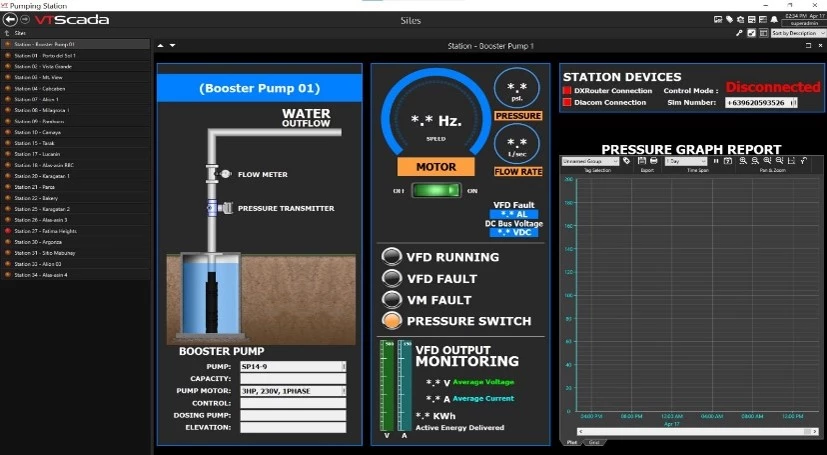

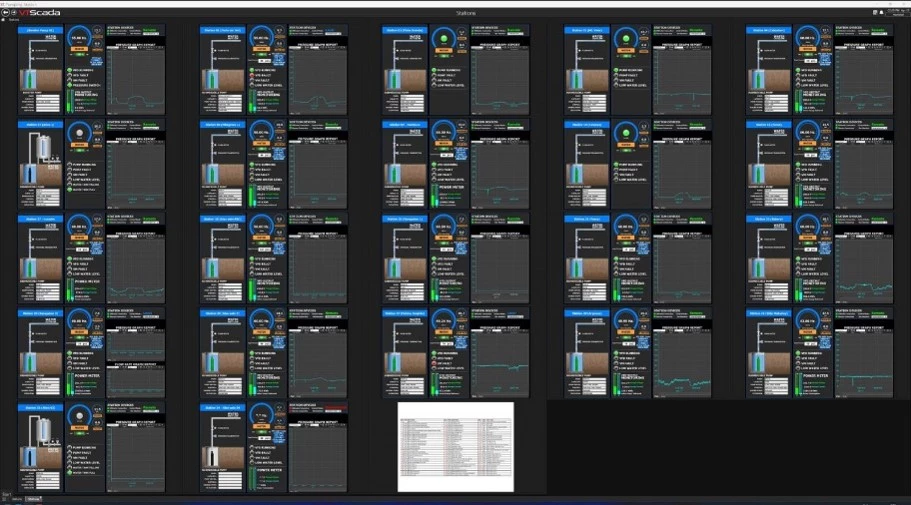

VTSCADA has comprehensive functionality, reliability, and flexibility,

enabling efficient

monitoring, control, and management of critical water infrastructure.

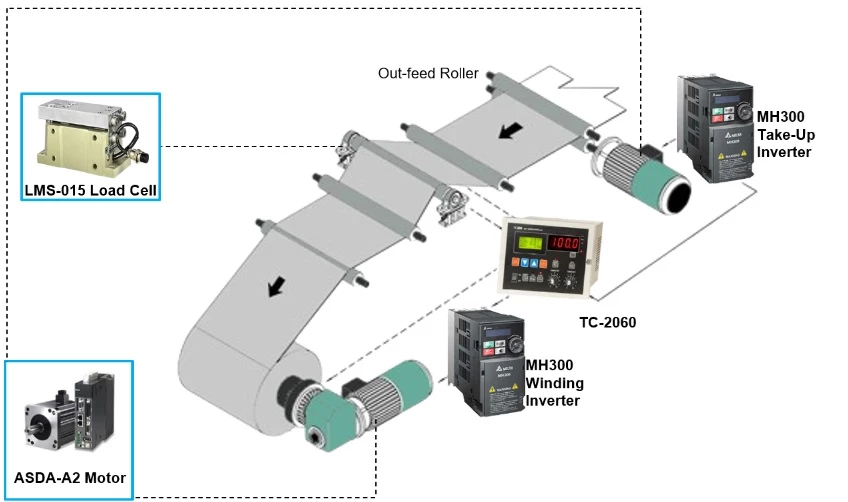

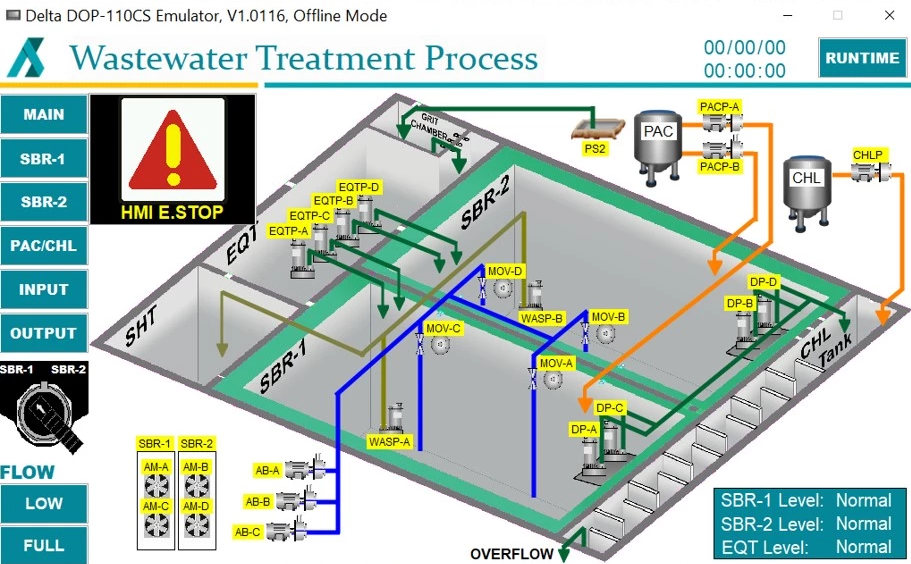

To ensure the smooth operation of water pumping substations within a district. A central monitoring station obtains real-time data on pump performance, water flow rates, pressure levels, and even energy consumption from sensors installed strategically throughout the substation. Modernizing the power supply systems with energy-efficient motors, variable frequency drives (VFDs), and optimized load management reduces energy consumption and operating costs. By providing a clear picture of substation activity, VTSCADA empowers water districts to enhance efficiency, minimize downtime, and ultimately deliver a reliable water supply to their consumers.